Print / download the product sheet

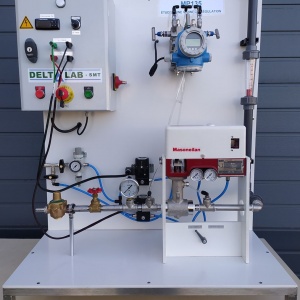

Print / download the product sheetThis bench allows the study of the characteristics of a regulating valve with pneumatic servomotor with needle. The concepts of CV and Kvs will be discussed. The valve will be used with or without positioner.

A pneumatic servomotor valve is supplied via the water supply via a needle valve. The flow is measured by a float flow meter. An expansion valve adjusts the pressure of the supply network.

The pressure difference between upstream and downstream of the control valve is measured using a differential pressure transmitter with local display.

The influence of the positioner on the response of the valve is determined by means of a current generator (4 to 20 mA) allowing the actuator of the control valve to be controlled via an I / P converter or via an electro- pneumatic positioner.

The device is mounted on a welded stainless steel frame.

It's made of :