Print / download the product sheet

Print / download the product sheetThe aim of this static test bench is the multiaxial study of the rotation guide of a shaft by different pairs of bearings - radial or angular contact ball bearings, tapered roller bearings -. The study is conducted under various modes of stress (axial, radial) with or without precharge of the assembly.

A specific simulation software is used in parallel to make the link between real and model.

Axial study with the basic version :

Multiaxial study with an optional instrumented shaft :

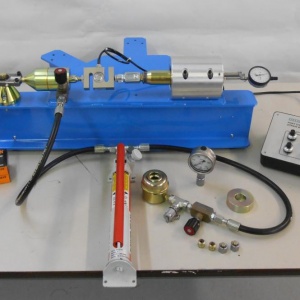

The test bench consists of a shaft and a pair of bearings assembled inside a rigid sleeve. A variable preload is applied to the guidance by a hydraulic precharge jack mounted on the shaft. Measuring the hydraulic pressure in this cylinder gives the value of the applied preload. A hydraulic load cylinder exerts a force on the shaft. A force sensor measures this load. These cylinders are powered by a manual hydraulic pump. A micrometer comparator measures the axial displacement of the shaft. The use of the instrumented shaft (strain gauges) allows the measurement of the preload of the assembly and the deformation of the shaft under axial and / or radial loading. An extensometric bridge is necessary for the operation of this test bench.

The standard equipment EX900 :