Print / download the product sheet

Print / download the product sheetThe EX1200 slitting system utilizes a UHING reciprocating box, a mechanism that converts the continuous rotation movement of a smooth shaft into a linear motion back and forth. Cinematically, they are like a screw-nut system. However two additional functions are ensured: the adjustment of the pitch of the screw-nut system and the change of the direction of the pitch (helix on the left or on the right). This last feature allows the change of direction of movement of the housing. Moreover, thanks to a special device, the reversal of translation direction of the housing is almost instantaneous.

These mechanisms are widely used in winding techniques. They are used to correctly distribute the wires or cables on a coil. Technically, for this operation called slicing, it is important to make sure :

- The system has a high-level mechanical appearance due to the complexity of the non-adjustable and reversible motion transformation case. It allows to conduct the functional analysis of the different functions :

Measure system performance (not setting, transferable effort before slipping, ....) Model kinematically the UHING system (shaft contact - bearing ring, pitch control system, .....) Conduct software modeling for step-change and direction-change bistable subsystems

- The electrical and control aspects are also paramount with the DC motor and its 4-quadrant inverter, the complete instrumentation (speed, position and force sensors)

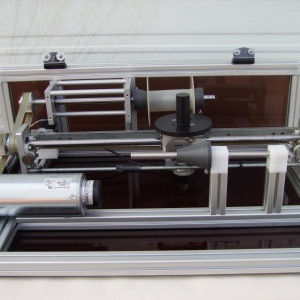

- A test bench comprising

- A UHING box mounted on a support with a device for implementing a cutting operation. Two coils make it possible to adjust the device and to realize this

operation with wires of different diameters

- A DC motor;

- Sensors make it possible to measure in real time : The speed of rotation of the engine by tachometer generator;

The speed of translation of the housing by generator tachymeter

The motor current, picture of the couple

The angular position of the axis of the bearing forming nut as a function of time during the period of reversal by potentiometric sensor

A force sensor to test the sliding limit force

- A control box with :

- A 4-quadrant electronic dimmer. The input commands imposed on the motor by the drive are of the type: speed step, speed ramp; sinusoidal speed

- An acquisition card provides access to a frequency of 10,000 Hz. This level of measurement allows to study the reversal phase which lasts about 0.1 seconds.

- A display for the rotation speed of the motor

- A switch for operation in manual or software mode

- Control and acquisition software