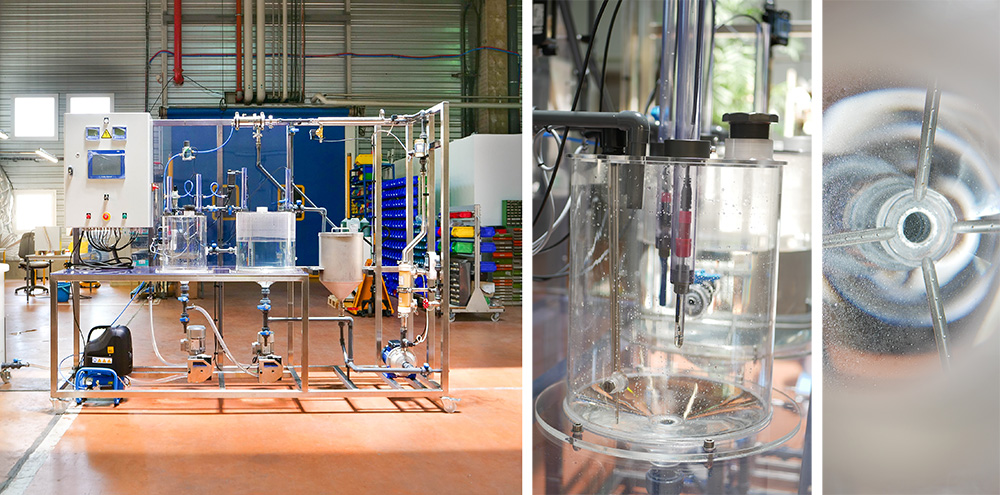

The BRM pilot makes it possible to understand and manage the wastewater treatment process by denitrification and nitrification. The operation is visual, since the products are used in Altuglas containers.

A set of microorganisms contained in a reservoir degrade the organic matter coming from an incoming effluent. This consumption leads to the growth of the biomass which settles. The separation between the water to be treated and the microorganisms is therefore done by density difference. Thanks to industrial instrumentation allowing continuous measurements, degradation phenomena can be interpreted almost directly (measurements of dissolved oxygen, energy consumption, etc.).

Laboratory analyzes are however necessary (COD, BOD). The operators will be able to manage their treatment station according to the following parameters:

Operators will be able to simulate increases in feed rates and react accordingly or generate malfunctions (oxygen level too low, acidic pH, etc.). It is obvious that all these phenomena are quite slow and that it is a question of carrying out daily readings and analyzes and of correcting or interpreting a situation.

A Pakistani university (Mehran University of Engineering and technology) in Jamshoro in the south of the country trusted us for the development of this material. This pilot will be used for research in one of their laboratory on the study of bio essence.