NUESTRO NEGOCIO

Nuestro negocioLa compa√Ī√≠a

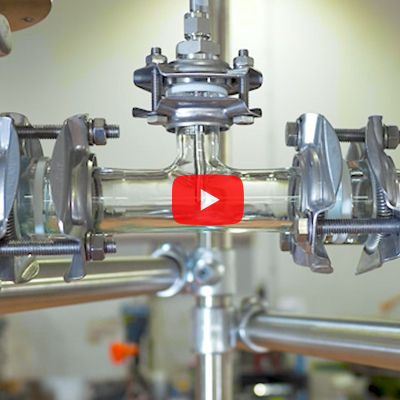

NUESTRAS M√°QUINAS

Agronegocios, productos farmacéuticos y biotecnologíasIngeniería químicaTratamiento de agua y desechosTermodinámicaHidráulicoRegulación y AutomatismoIngeniería AutomotrizIngeniería MecánicaEnergía renovableAerodinámica

CONTACTO

NOTICIAS