"Depuis 1967, DELTALAB propose une large gamme de produits pour l'enseignement général, l'enseignement scientifique, professionnel et technique, la recherche universitaire et industrielle.

Un catalogue de plus de 300 références.

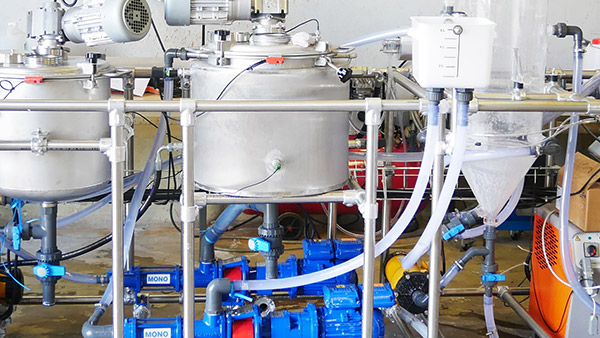

Du matériel de base à la chaîne de production pilote , notre Bureau d'Etudes pluridisciplinaire (mécanique, automatisme, électronique, génie des procédés, systèmes de communication...) conçoit, développe et teste les produits dans le respect des référentiels pédagogiques et de votre cahier des charges. Notre Service SAV gére l'installation, la mise en route des produits et à la formation in-situ."